PRODUCT FEATURES

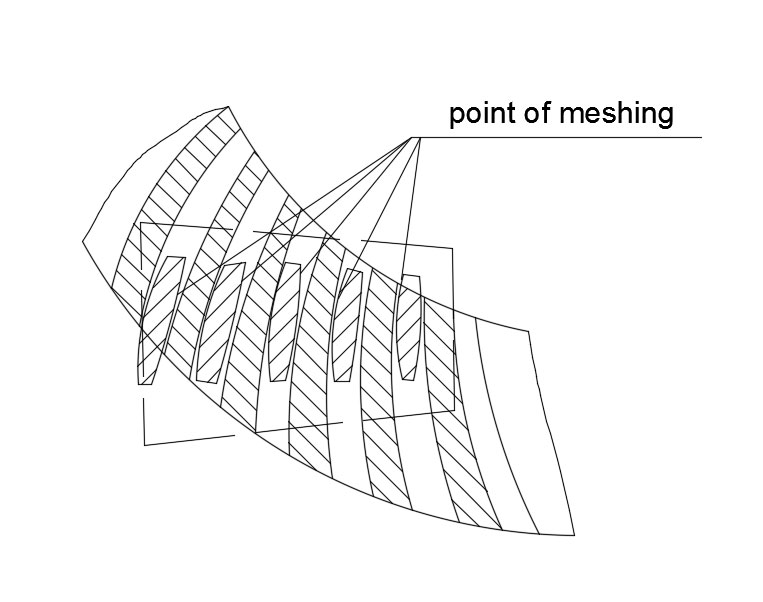

1、Large contact ratio, more teeth in meshing, high loading capacity

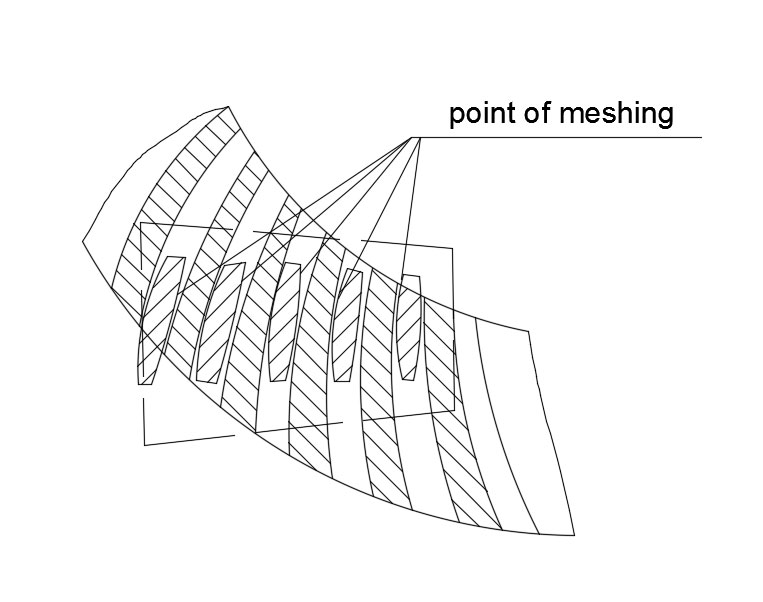

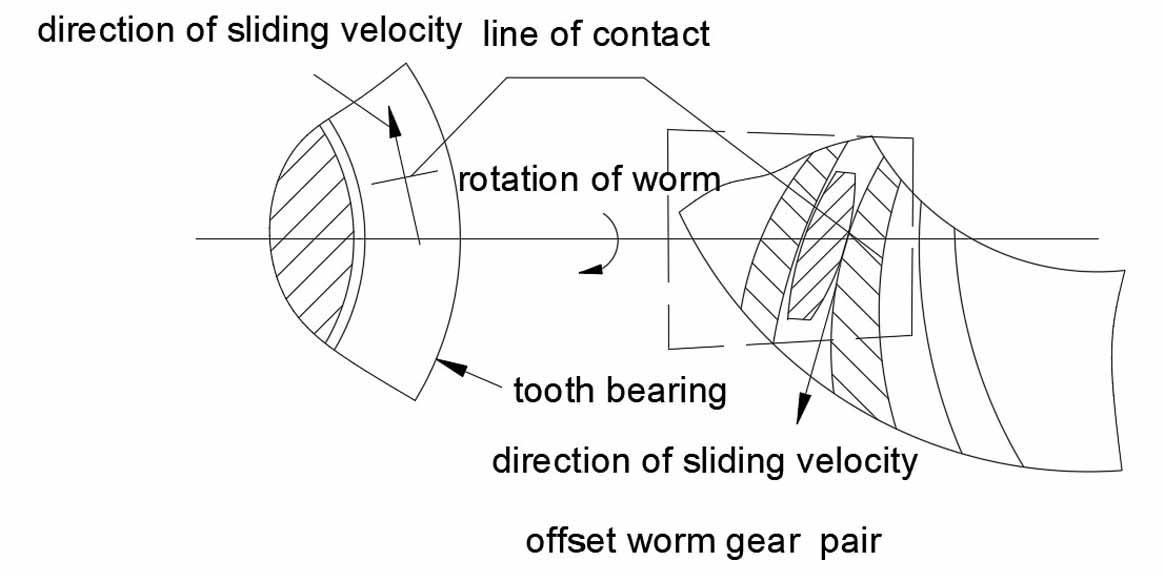

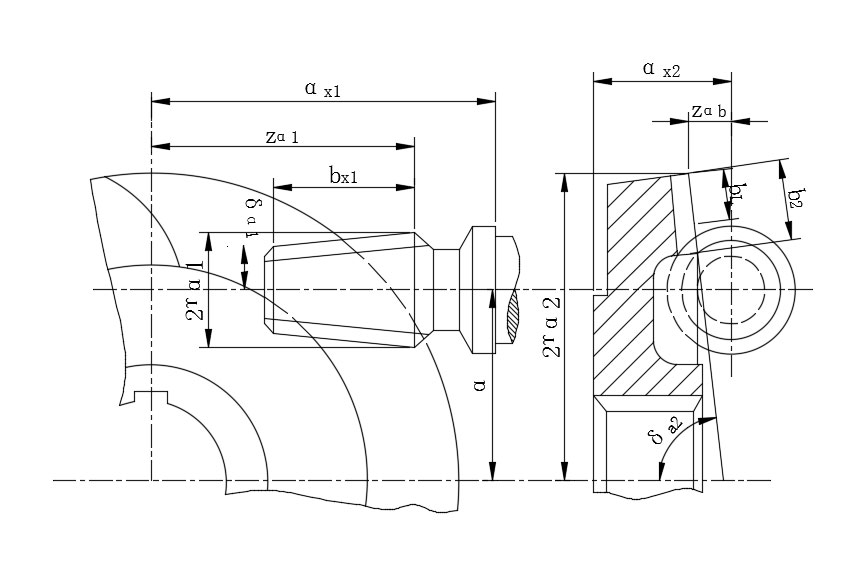

As shown in figure, offset worm is placed across the end face of offset worm gear with more teeth in meshing. Usually 10-12% of the number of offset worm gear teeth in meshing. For example, a offset worm gear has 50 teeth, then it will have 6 teeth in meshing with the offset worm. With more teeth in meshing, the line of contact will be longer, and the curvature radius at the contact point is much larger than that of cylindrical worm gear pair, so offset worm gear pairs can endure higher load, transmits larger power. With the same transmission power, its center distance can be reduced up to 40%. So the offset worm gear pair has compact structure, smaller size and lighter weight.

2、The shape of instantaneous line of contact of spiroid gear drive can facilitate the formation of hydrodynamic oil film between the conjugate tooth surfaces. The tooth surfaces have excellent lubricating property.

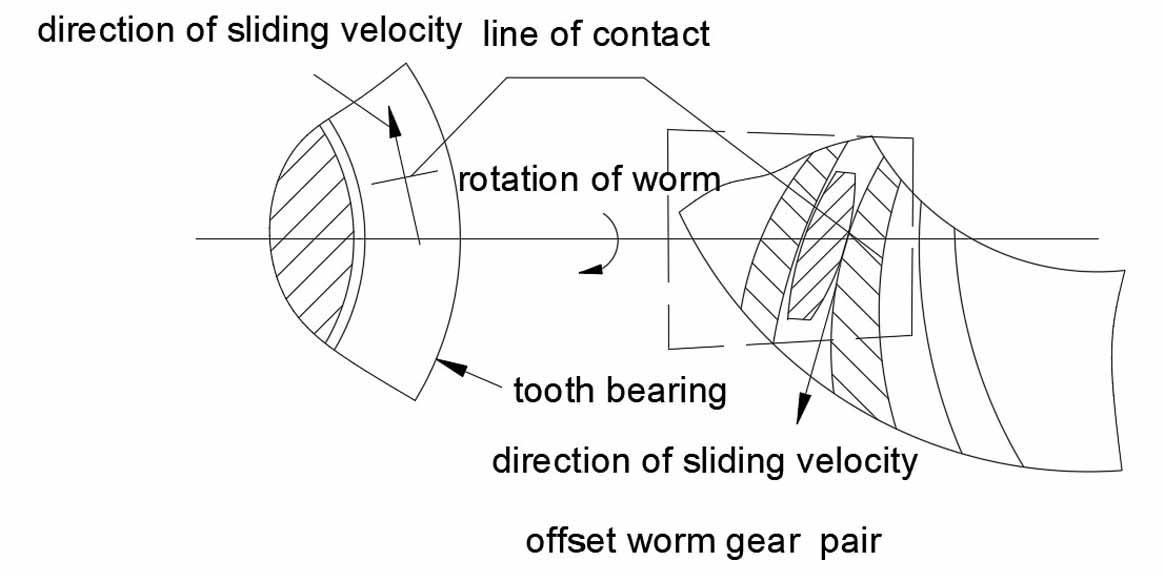

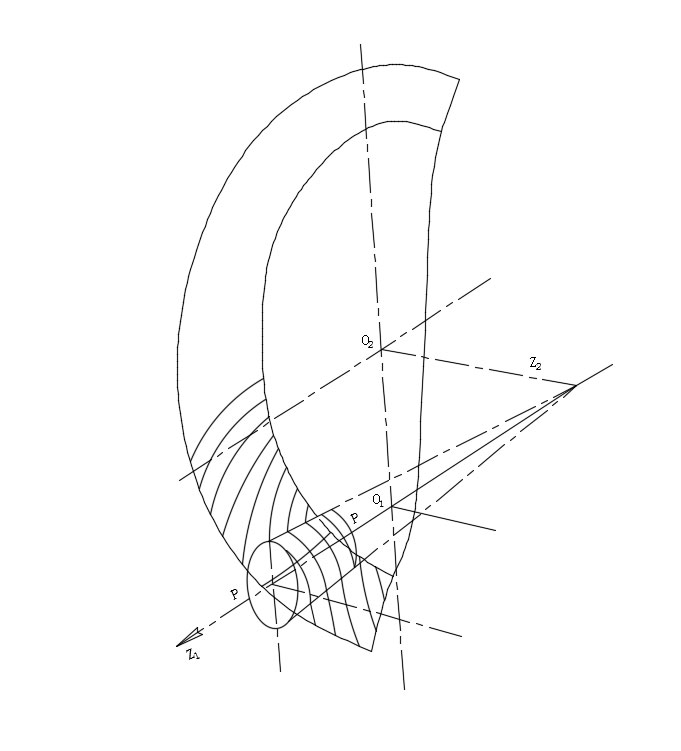

The angle between the tangent line of the instantaneous line of contact and corresponding direction of relative movement is a key factor for the worm transmission performance, such as efficiency, service life and loading capacity. The larger the angle is, the better the transmission performance will be. As shows in figure, the instantaneous line of contact of spiroid gear pair is almost a radial line, the angle between it and the direction of movement is close to 90°, which is helpful for the formation of lubricating oil film and improvement of the loading capacity of the tooth surface. In addition, the line of contact slides into the entire tooth surface at a high speed, this can also benefit the formation of lubricating oil film and improvement of tooth surface strength.

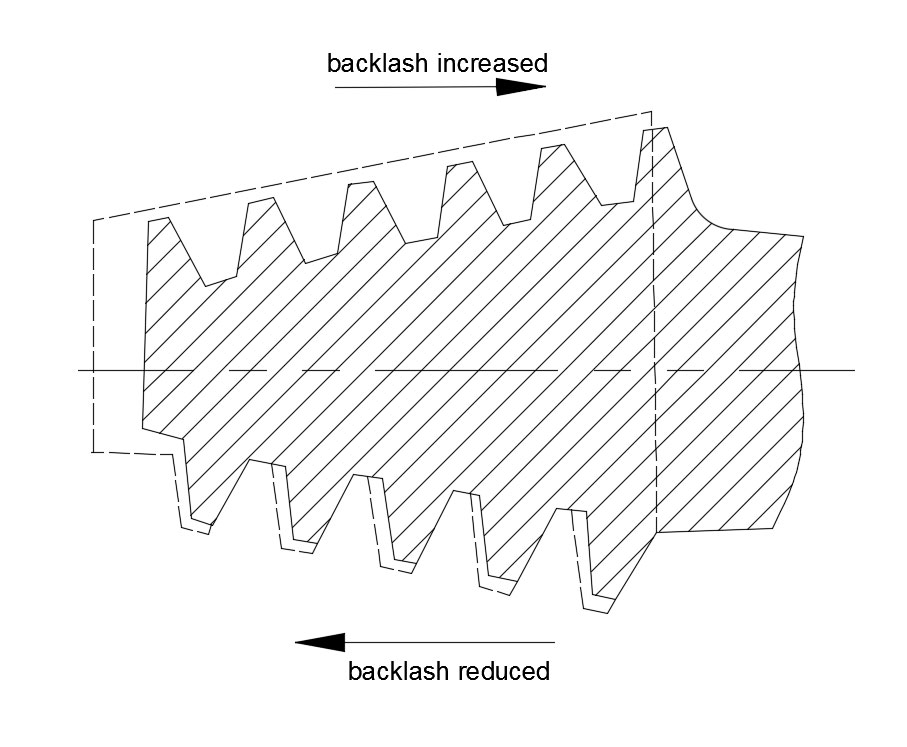

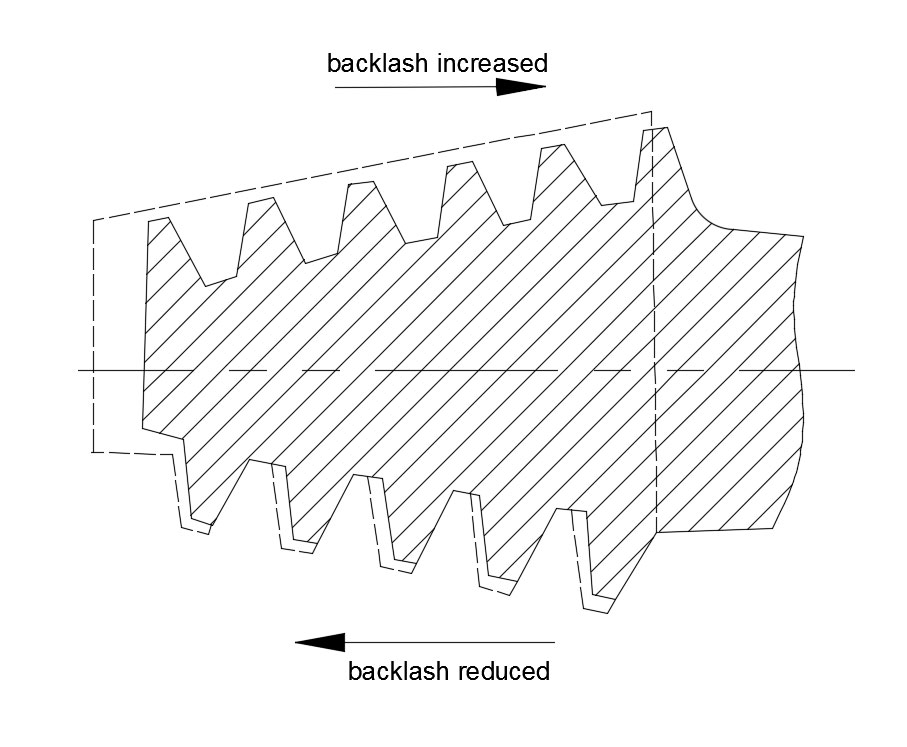

3、Backlash is adjustable. It can achieve zero backlash, has good meshing property, and can also be used as a clutch.

Because of the geometric properties of offset worm gear pairs, when the offset worm or offset worm gear is properly adjusted along the axial position, it will not destroy the conjugation between the tooth surfaces and will not affect their contact. When moving the offset worm, the backlash can be fine adjusted; When moving the offset worm gear, the backlash can be coarse adjusted. Therefore, the requirements of backlash can be met by adjusting the position of offset worm and offset worm gear. It is impossible for any other type of worm gear pairs to adjust the backlash so easily. The offset worm gear can also be moved along its axis for a long distance, so that the offset worm and offset worm gear can be easily disengaged and engaged, in this way they can also be used as clutch. And the center distance remains unchanged when disengaged. It can rotates in left and right, so that it can transmit the power in two directions.

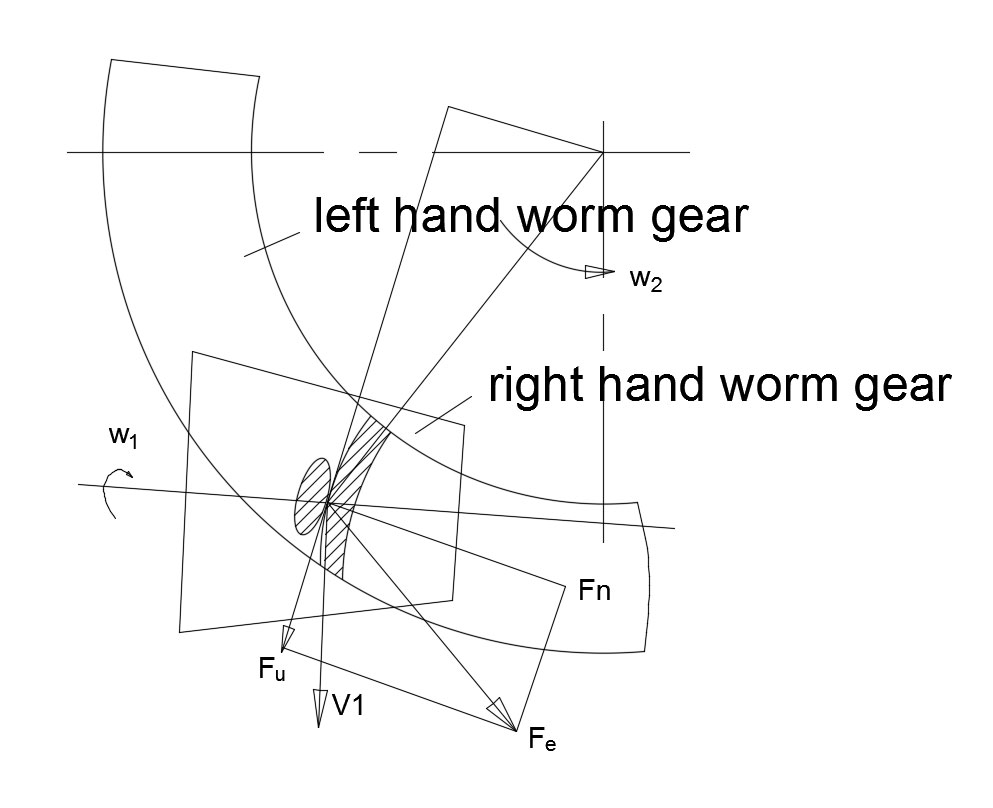

4、High transmission efficiency, smooth operation and low noise level

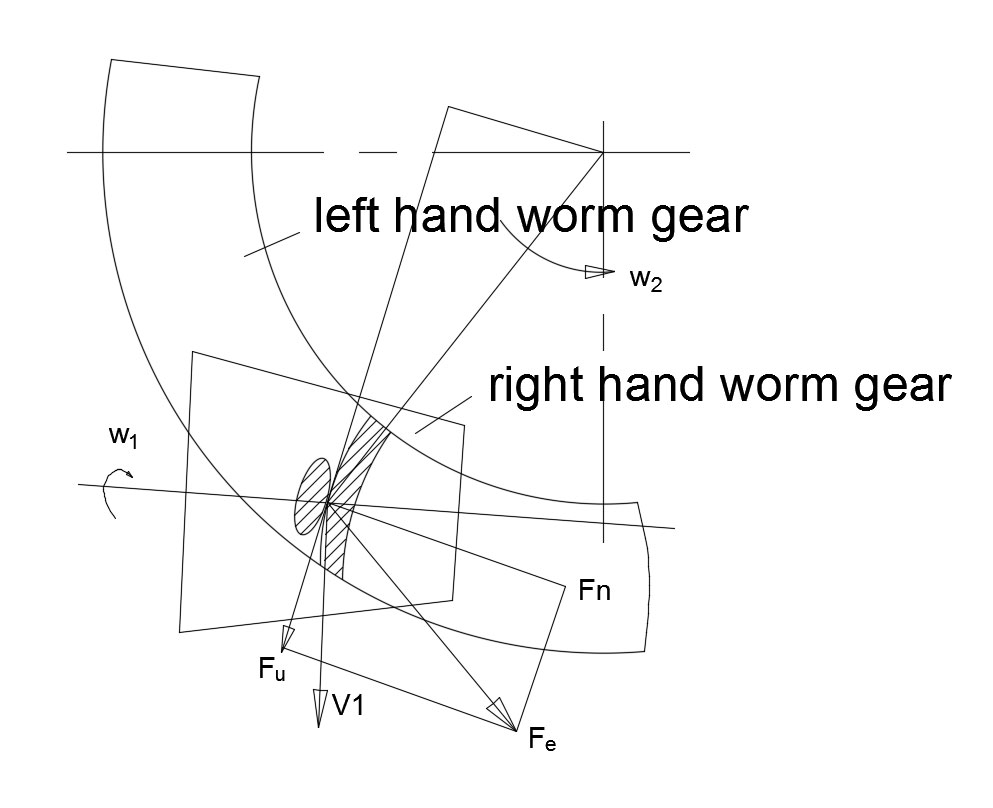

Offset worm gear pairs are not only has better lubrication, but the friction between the tooth surfaces is helpful for the rotation of the offset worm gear. As shown in the Figure, both friction force Fu and normal force Fn make the offset worm gear rotation in the same direction. So when the offset worm and offset worm gear has proper rotation direction and transmission position, it can achieve high transmission efficiency.

Compared with ZC type worm gear pairs:

- Loading capacity increased by 60%~150%

- Transmission efficiency increased by 10%

Compared with ZA type worm gear pairs

- Loading capacity increased by 200%~300%

- Transmission efficiency increased by 15% ~ 20%

5、Larger ratio range: 3:1 ~ 400:1. it can achieve self-locking, if needed.

MAIN PRODUCTS & APPLICATION

MAIN PRODUCTS

Custom made spiroid gear pairs

- Minimum center distance: 12 mm

- Maximum center distance: 70 mm

APPLICATION

-

Aerospace

-

Nationaldefense

-

Medical instruments

-

Robot joints

-

Indexing device of tooling

-

Precise apparatuses and instruments drive

-

Radar antennas

-

Agricultural machinery

-

Lifting machinery

-

Packaging machinery

-

Power wheelchairs

-

Scooters

-

Booster pump used on automobile

-

Automobile pedals

-

Electric windows and doors

-

Food machinery

-

Power tools

DESCRIPTION

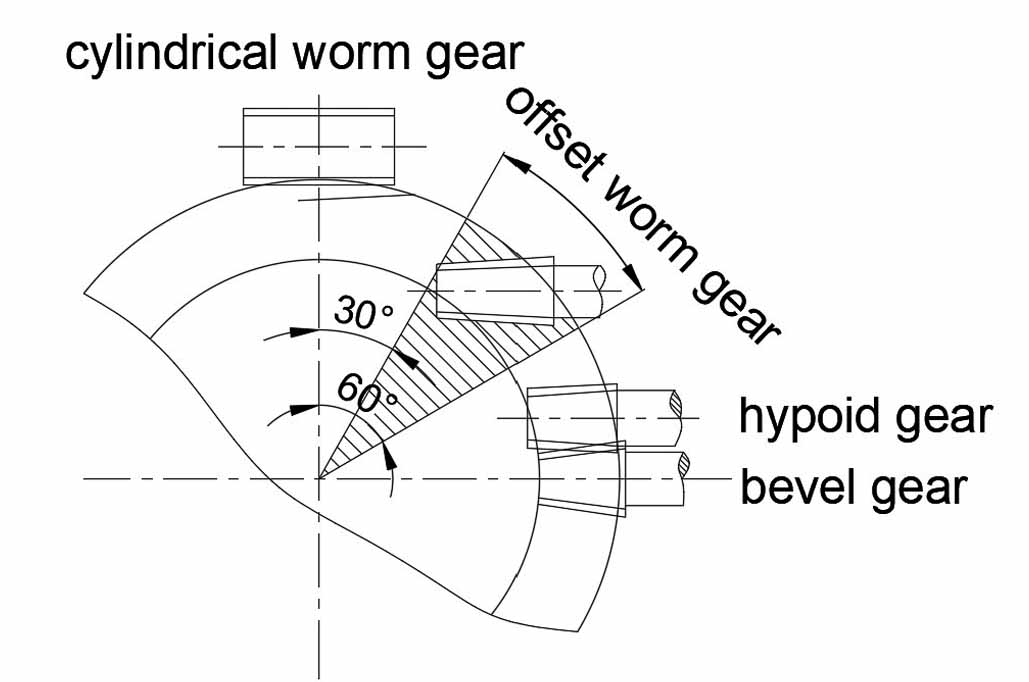

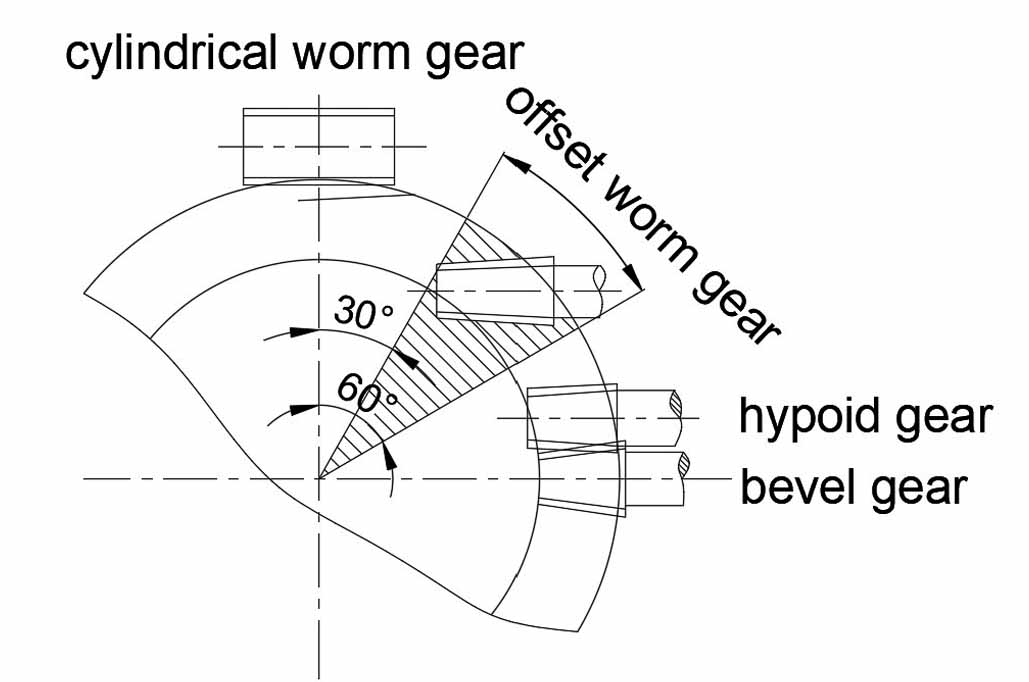

Offset cone worm gear pair is operate on nonintersecting, nonparallel axes. It involves a tapered pinion that somewhat resembles a worm. The offset worm gear is a face gear with teeth curved in a lengthwise direction; the tooth is like a helix angle-but not a true helical spiral. Figure shows the schematic relation on the offset worm gear pairs to cylindrical worm gears, hypoid gears and bevel gears.

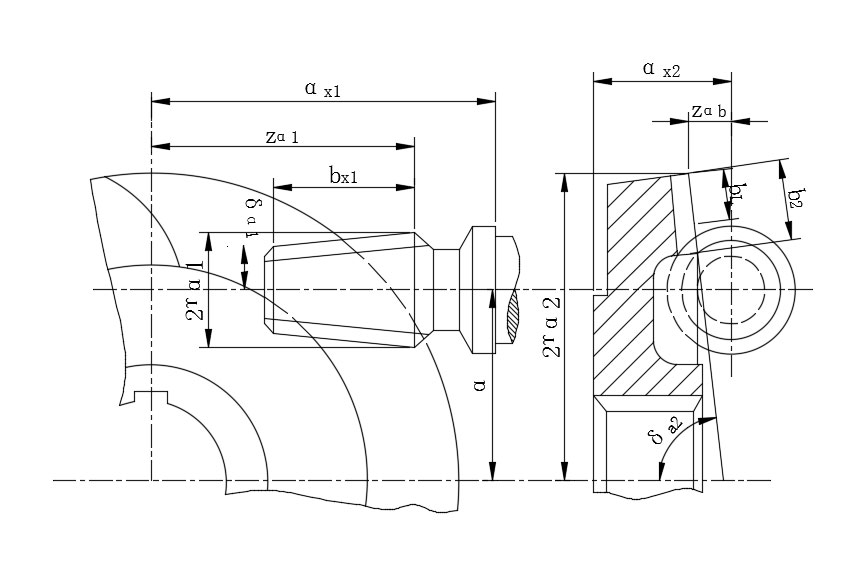

Generally, the shaft angle ∑=90°. The corresponding installation position of offset worm and worm gear is: the left hand of offset worm applies down offset, and the right hand of offset worm applies up offset.

The offset worm gear pair has the cylindrical type and the cone type. The cylindrical type is essentially a cylindrical worm with no taper. The cone type is essentially a worm with taper.

The offset worm gear pairs are used in a wide variety of applications, from aerospace actuators to automotive and appliance. The combination of a high ratio in compact arrangements and good load-carrying capacity makes the spiroid gear pairs attractive in many situations.

Compared with cylindrical worm gear pair, offset worm gear pair has the following features: the shape of contact line is favorable for the formation of hydrodynamic oil film, and on the conjugate tooth surface, during the meshing process, the instantaneous contact line slides across the whole tooth surface, which creates good condition for lubrication and the cooling of tooth surface; at the same time, the meshing tooth number accounts much with large overlap ratio; single driving itself can make large transmission ratio (i=10~400); at the meshing point, the sliding speed of conjugate tooth surface is slow; ideal meshing characteristics can be easily realized.